High-pressure industrial rolling mills

Electric rolling mills for industry and livestock

TOY Group High Pressure Rolling Mills

For industry and electric motor farming or for power-up agriculture, the TOY Group has implemented high-level technology for these high-pressure rolling mills. The precision of the manufacture of these industrial machines, as well as the innovations on the transcoblock technology cylinders, the high hydraulic pressure of 3 to 15 tons, the independent drive of each cylinder, the protection by nitrogen sphere, make our rolling mills high-end equipment, Download the brochure: TOY Group Solutions Industries

*Indicative flows, depending on the grain and humidity. For optimal quality: recommended humidity level from 14 to 16% .

Non-contract photos and info, subject to change without notice – see us

Electric rolling mills: from 900 to 10200 Kg/H

6 electric rolling mills models

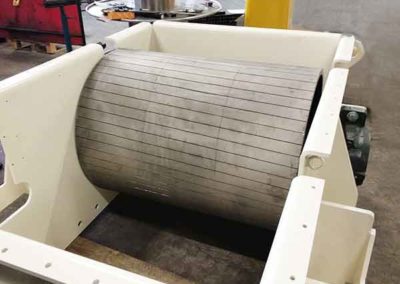

With flows from 900 to 10200 KG/H for powers of 6 to 37 kW. TOY Group electric rolling mills are equipped with transcobloc cylinders of (diameter X L in mm) 500X250, 500X450, 500X650, 800X450 or 800X850. Hydraulic pressure between cylinders ranges from 3 to more than 15 tons and offers optimal and regular work quality and high flows.

6 models of Electric Rolling Mills with flow of 900 to 10200 KG/H. POWERS FROM 6 TO 37 KW. THESE ELECTRIC LAMINOIRS have TRANSCOBLOC TYPE CYLINDRES from 500mm to 800mm and lengths from 250mm to 850mm.

TOY GROUP ROLLING MILLS: THE TECHNIQUE

Training by two groups:

- Independent geared motor cylinders drive.

- Industrial-series gearboxes.

- High torque geared motor, easy load restart.

- Technology without belts or chains, easy maintenance.

High hydraulic pressure 3 to 15 tons: - Tightening principle: 2 hydraulic jacks push the mobile cylinder on the fixed cylinder (from 3 to 15 tons of pressure).

- Cylinders supplying : hand pump tightening (control gauge)

- Precise adjustment of the cylinder spread.

- Fixed pressure for a regular work quality.

Safe rolling: - Hydraulic circuit with nitrogen sphere (cylinders kickback if abnormal pressure)

- Racing cylinders setting with double-stop anti-crash cylinders.

- Rolling mills equipped with sieve and magnet ramps.

- Scrapers installed to ensure cylinders cleanliness.

TOY GROUP ROLLING MILLS: THE QUALITY

Innovative large-diameter cylinders:

- Steel of heavy treated thickness. Intermediate flasks and reinforcement flasks guaranteeing solidity. A whole high precision balancing.

- diameter 500 to 800 mm provide the ideal angle of introduction(Nippel angle) for the passage of large seeds (peas or corn).

Transcobloc-type technology:

- Preservation of tree strength and bending characteristics by seamless assembly (Transcobloc-type technology).

Accurate and constant flow:

- Inverted screw feeder for regular and constant feeding of cylinders. Geared motor with a dimmer for precise adjustment of production flow.

Options

- Motorized hatch

- Cylinders treated with carbonitriding gas (longer life).

TOY ROLLING MILLS: 6 MODELS FEATURES

|

Electric rolling mills: models and features |

||||||

|

Models |

500X200 |

500X400 |

500X600 |

800X400 |

800X800 |

800X1000 |

|

Cy cylinders: X L |

500X250 |

500X450 |

500X650 |

800X450 |

500X850 |

800X1050 |

|

Average flows (Kg/h) |

900 to 1200 |

3900 to 4600 |

5900 to 6600 |

4000 to 4700 |

7200 to 8600 |

9000 to 10200 |

|

Electrical power (kW) |

6 |

15 |

22 |

15 |

30 |

37 |

|

Pressure between cylinders (Kg) |

3000 |

4100 |

6100 |

8200 |

13300 |

15200 |

|

Indicative flows, depending on grains and moisture tx. For optimal quality: humidity tx recommended from 14 to 16% . |

||||||

Rolling mills: Special models

Special rolling mills

Depending on the activity, depending on the specifics of production and the implementation of the machines. TOY Group designs and produces your special rolling mills.

Design and production of special ROLLING mills TOY Group according to your production specifics and the implementation of the machines.

TOY GROUP ROLLING MILLS: SPECIAL MODELS

Some typical special models:

- On a blender

- On chassis/rail

- Bucket loading hopper

- Loading / Endless screw output

- …

SPECIAL MODEL ROLLING MILLS: FEATURES

Same general and technical characteristics. Or according to specific models

- Drive cylinders by independent industrial geared motors.

- High torque geared motor, easy load restart.

- Technology without belts or chains, easy maintenance.

- High hydraulic pressure 3 to 15 tons:

Principle of tightening: 2 hydraulic jacks push the mobile cylinder on the fixed cylinder (3 to 15 tons of pressure). - Cylinders supplying : hand pump tightening (control gauge)

- Precise adjustment of the cylinder spread. Fixed pressure for a regular work quality.

- Nitrogen sphere (recoil of cylinders if abnormal pressure)

- Equipped with sieve and magnet ramps. Scrapers installed to ensure cylinders cleanliness.

- Innovative large diameter cylinders

- Treated steel. Intermediate flasks and reinforcement flasks. A whole high precision balancing.

- diameter 500 to 800 mm allow you to get an ideal angle of introduction.

- Transcobloc-type technology

- Inverted screw feeder. Geared motor with a dimmer for precise adjustment of production flow.

Options

- Motorized hatch

- Cylinders treated with carbonitriding gas (longer life).

Some industrial rolling mills TOY Group

Industry Contacts

Industry salesman : Benjamin Ollivier

Tel: 06 80 33 12 38

b.ollivier@toy-sa.com

Industry Project Assistant: Muriel Faucheux

Tel: 02 54 85 29 63

m.faucheux@toy-sa.com

General reception desk

Tel: ’33 (0)2 54 85 01 10

Fax: ’33 (0)2 54 72 60 67

info@toy-sa.com

TOY Group Montoire sur le Loir

Route des Reclusages 41800 Montoire sur le Loir