Automation, weighing, sensors, switch cabinets

From soft and automata to sensors and sensors, a TOY Group’s complete control of your processes

Monitoring your machines and process

In this section, find all automate’s tools and control your equipment and your TOY Group process chains. Production unit management of software and automata, multi-site multi-tasking, automated unit management and handling chains, preserving storage and monitoring of storage units. As well as all the dosing and weighing equipment and switch cabinets of the TOY Group. Download the brochure: TOY Solutions Industries Group

Non-contract photos and info, subject to change without notice – see us

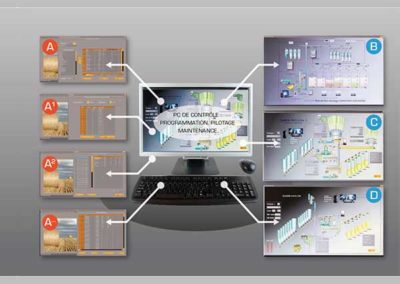

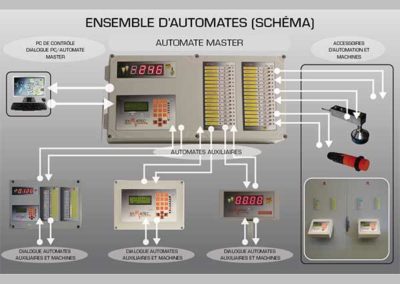

PC and automation piloting

Control PCs and automatons

Developed within the René TOY group, flexible and adaptable and scalable steering of all productions. A SYMAFAB, SYMAGUARD, SYMASTORE software suite, and sharp automatons help manage all needs.

A SYMAFAB, SYMAGUARD, SYMASTORE and automatons software suite help manage all needs.

PC and Automates:

Developed within the René TOY group, the new sets of automatisms provide piloting possibilities suitable for all productions. These systems have great adaptive flexibility and scalability. A symAFAB, SYMAGUARD, SYMASTORE software suite manages all needs. Our various-capacity automatons are suitable for automating all weighing machines.

Some examples of installations :

- PC control and control of production units.

- Software Suites: SYMAFAB / SYMASTORE / MULTIDIS / SYMADIS / MATERDIS / SELFIDIS

- Dynamic synoptics

- LC9 : 16 recipes / 6 products

- 4-threshold display : 1 formula / 4 products max

SYMAFAB Software: Power Plan Management

SYMAFAB

The manufacture of livestock feed involves the use of a wide variety of raw materials, some in large proportions, others in minute proportions. The location on the site and the presentation of these materials is often very diverse. The required flows vary greatly depending on the expected daily production requirements and the mandatory traceability. SymaFab provides an adaptive and scalable solution capable of responding to different manufacturing configurations, from the smallest or simple structure to the largest and most sophisticated. (Simplified automaton – automaton 32 relays)

The benefits:

- Weighing per kilo of crushed or un crushed products;

- Weighing 100g for more sensitive products;

- Weighing at 10g for highly sensitive products (food supplements, medicines, vitamins, etc.)

- Single-site or multi-site manufacturing supervision with animated synoptics

Several multitasking automatons can be networked when different dosing sites are required. A multi-site formulation is split across multiple sites depending on the expected accuracy or location of the raw materials. The sites working simultaneously allow a high speed of manufacture. Distribute your manufacturing directly to your power plans. This will give you a temporal, quantitative and adaptive evolution.

Optional for shredders:

- Regulating the shredder’s supply for optimal operation regardless of the product to be crushed

- Setting a grinding speed by product and formula to get the desired granulometry on the product ends

- Managing several shredders

SYMASTORE software: transport, handling, storage

SYMASTORE

Our solution operates on the reception of materials, handling and transport to storage sites, as well as the conservation and monitoring of materials on site. Our SymaStore concept is fully configurable and scalable over time, it adapts to any type of installation, without additional extra cost of customization. You can handle handling very instinctively and start several handlings simultaneously. Our software is fully configurable to adapt to your environment. You will also optimize the ventilation of your silos: SymaStore monitors and regulates the conditions of conservation (temperature, humidity) in the silos by automated ventilation.

The benefits:

- An automated /PC solution for automated management of storage sites, for small and large structures

- Handling and Storage

- Optimize the ventilation of your silos

Our system allows:

- The reception of materials (optional weighing)

- Handling and transport to storage sites

- The synoptic programming of paths between source and destination of materials. This avoids switching and jamming errors

- Repeated measurement of temperature and optional hygrometric conditions

- Functional supervision of ongoing handling

- Level management

- The association of cells or silos with one or more fans over staggered periods

- Cumulative ventilation times, airflows brought into silos if fan flows are reported

- Tracking the history of silos measurements on the various probes (temperature, humidity…)

- The edition of temperature change curves in silos over several months

- Automaton optional supervision software on PC or touch tablet

- Fan starts and stops either automatically next to the instructions or by optional staggered start to avoid a major power call

- Optional silo level tracking

- The programming of ventilation time slots

MULTIDIS SYMADIS MATERDIS SELFIDIS Software: distribution

For distribution management, TOY Group offers various software:

MULTIDIS SYMADIS MATERDIS SELFIDIS

Benefits of different systems:

- Quantitative and qualitative feed curves, defined on a day-to-day basis

- A supply of fresh food in quantities optimized for each meal

- Nutritional optimization by an age-appropriate formula

- Smooth transitions to avoid disruptions

- Decrease in nitrogen, ammonia and phosphorus releases

- A date-to-date history for detailed visualization of the manufactures.

MULTIDIS

Multidis is a dry, multi-phase food manufacturing and distribution system capable of distributing via pneumatic or mechanics. It allows a seizure of several feeding planes with a quantity and an evolutionary composition every day life of the animal. A valve is then indexed to a power plane with day-to-day transition. You can thus supervise in real time the distribution of your food by precisely dosing small quantities at the valve (case), optimizing the doses to valve (case) in quantity and composition but also saving time and efficiency by dosing and distributing simultaneously. MULTIDIS Scheme

You will effectively monitor and adjust your power plans. Consumption index is referred to as a performance index: it shows the number of kilos of food distributed per kilo of growth. This index differs depending on the stage of life of the animal: it will be lower at the beginning. Its growth is rapid: at the end of fattening, it increases. That is, he doesn’t believe much anymore but he needs a lot of food to maintain his knowledge. By playing on a distribution adapted in quantity and composition on a day-to-day basis, you can, as a breeder, influence your consumption index: we are talking about a feeding plan that you can refine to get the lowest possible index and therefore a better performance. You’ll keep a detailed traceability by viewing your manufacturing and distribution data on your computer at all times and will control every component of a distribution/manufacturing. You can also export them easily for your ERP.

In summary, MULTIDIS will offer you:

- A dosage of 10g by multi component in a preparation tank with simultaneous distribution to the valve

- Distribution by chain or pneumatic system

- It allows one-off rationing on a given day of the week

- Speed pneumatic distribution

- Detailed manufacturing/distribution traceability on your computer (pc)

- A weekly schedule

- The pneumatic distribution that ensures distribution channels purged in the air: no cross-contamination

SYMADIS

Symadis is a multi-phase dry food manufacturing/distribution system capable of a pneumatic distributing of food with a high content of moist maize (up to 70). It allows a seizure of several recipes. A valve or valve group is then indexed to a feed plan with a revenue transition. The use of different forms of wet maize has developed in France in pig farms thanks to its economic advantages (savings of drying costs, recovery of maize from the farm, …) and techniques (early harvest, optimal yield, traceability, …). It also allows for more self-contained access to large fluctuations in food prices.

Technically, tests show an improvement in the consumption index compared to dry maize. Its high energy value makes it an excellent raw material for deli pigs, and its natural acidity helps in the control of digestive disorders.

Multi-phase feed through recipe transition:

- Defining recipes

- Definition of revenue transition plans with varying amounts on a day-to-day basis (female plan, male plane, sow plan, sausage maker plan, etc.) at the valve

- Fresh food in quantities optimized for each meal

- Nutritional optimization with an age-appropriate recipe

Gain performance with our SYMADIS automaton:

- Wet corn transportation up to 70%

- Distribution circuits purged in the air: no cross-contamination

- Fast distribution

- Sharp history on pc, fabrications/distributions

- Allows one-off rationing on a given day of the week (abattoir departure)

- Weekly planning. SYMADIS Scheme

MATERDIS

MaterDis is a food distribution concept optimized for feeding sows in maternity wards. During the maternity period, the animals are in a fragile situation, especially in the days before and after the calving. MaterDis is a tool to help optimize tasks and support you in performance. This system supports animals at various ages of development. For primipares, adults, animals at the end of their careers, their food needs are very different. On the other hand, throughout the period of presence in the maternity ward the animals are subject to potential events that vary greatly from one individual to another. The ambition of the MaterDis system is to manage the whole food problem and its implications as best as possible, both technically and economically. Its goal is to be able to serve several meals a day in optimal conditions and thus:

- Avoid leftovers not consumed in trough

- Ensure a fair diet

- Managing watering

- Ensure clean and fresh food consumption at all times

- Contributing to the best possible health

The benefits:

- Loss limitation: By splitting a meal into several basic dose proposals. At each basic dose proposal, a trough check (full/empty) is carried out. Depending on this test, the dose is distributed or not. The distribution of a meal continues as long as the quantity to be served according to the food plan is not reached or as long as there is still a credit of food proposals.

- A food plan specific to each category of animals: MATERDIS adapts to each category of animals by memorizing their database (primiparous, adults, animals at the end of their careers). They trace the temporal, quantitative and qualitative evolution, as well as the modalities of distribution for each animal. These plans allow for proper feeding and avoid potentially lethal overconsumption for the animal.

- Evolutionary meal splitting: In order to avoid the distribution of too many small basic doses, it is planned to distribute doses in evolutionary quantities, depending on the distance from the critical area of calving or a health event. This evolutionary variation in doses is driven by the different feeding planes on which sows are fed.

- PC or tablet supervision: Depending on the potential refusals found, and the speed of consumption, a consumption profile emerges. The data is stored on a historical file that can be easily accessed, via pc or tablet supervision, which becomes an effective management tool for predicting health events. It allows for early detection of trends. The supervisor screen produces control and alert tables prioritized according to the events observed on the troughs, the alert levels red, orange, green are incentives for more or less urgent actions suggested to the breeder. All consumption hisisms are preserved and easily exploitable.

- An individual description sheet: It supports all the data instructions and characteristics specific to each animal (age, room number, plan number, weight, daily ration…).

- The possibility of multiplying meals (food or water): For stimulation of the sow (animal welfare).

Maternity Photo – MATERDIS Scheme

SELFIDIS:

In pig farming, new European animal welfare standards have led to the breeding of pregnant sows to group farming. SELFIDIS is a system for distributing dry food and water for sows gestant in static groups (composed of sows of the same band), with electronic badge identification (RFID). This system allows appropriate tracking for each sow, as well as a gain in the living area. When a sow shows up on a station, it is automatically identified with its electronic badge. The automaton then delivers the dose assigned to the sow according to its positioning in its feeding plan. The aim of this concept is to offer a system as accurate as possible, simple and reliable over time, made possible by the use of digital piloting.

The benefits:

- Recognition of the sow by its electronic badge (RFID technology)

- Managing the closure of the station’s doors during the feeding period, to avoid aggression

- Precise dosage according to the positioning of the sow in its feeding plan

- Split distribution during the day

- Distribution of water that can be adapted to the amount of food distributed

- Management of refusals thanks to a probe of the presence of food in the trough, allowing a reduction of waste

- Supervision on pc (animal database, alert rise for unnoured sows, consumption history). 2 SELFIDIS schemes

Dosing/Weighing

Weighing sensors, weighing frames…

TOY Group offers weighing solutions adapted to its equipment and various processes (food manufacturing and others). Chassis weighs 3 or 4 gauges to measure, depending on the equipment mounted. Individual weighing sensors for mixers, load bushels, etc.

Chassis weighs from 1 to 10 m2. Individual sensors for various equipment. Weighing for loading bushels…

Dosing/Weighing: Weighing Chassis

Our weighing frames are equipped with 3 or 4 gauges depending on the stability of the load to be supported. We adapt the custom dimensions, depending on the clutter of the material mounted on it. They are adaptable on all our types of blenders. From 1 to 10 square metres of surface area, our weighing capacity ranges from 500kg to 3 tonnes.

Dosing/Weighing: Sensors

Depending on the configuration of your equipment individual weighing sensors per foot can replace a weigh-in chassis (for mixers, food factories etc). Specific sensors are also available for loading bushels or other equipment. Check your technical-commercial for advice.

Sensors, sensors, accessories

All types of sensors for automatisms

Temperature sensors, capacitive sensors, rotary sensors, and all various sensors for automation

Temperature sensors, capacitive sensors, rotary sensors, and all various probes

Sensors and sensors

TOY Group provides you with all the sensors and sensors to automate your processes and machines.

- Temperature sensors;

- Capacitive sensors;

- Rotating detectors;

- …

Control cabinets

Control cabinets

Electrical cabinets designed and custom-made in TOY Group’s workshops All our cabinets are custom-made by us.

Chassis weighs 3 or 4 gauges. Bespoke. Surface from 1 to 10 sqm, weighing from 500kg to 3 tonnes.

Control cabinets

Our electrical cabinets are custom-designed and custom-made in our workshops. All our cabinets are custom-made by us according to the needs of your installation. The components are of the highest quality, to ensure a safe and reliable operation.

Automatisms Toy Group Examples

Industry Contacts

Industry salesman : Benjamin Ollivier

Tel: 06 80 33 12 38

b.ollivier@toy-sa.com

Industry Project Assistant: Muriel Faucheux

Tel: 02 54 85 29 63

m.faucheux@toy-sa.com

General reception desk

Tel: ’33 (0)2 54 85 01 10

Fax: ’33 (0)2 54 72 60 67

info@toy-sa.com

TOY Group Montoire sur le Loir

Route des Reclusages 41800 Montoire sur le Loir