MASH Food Production Units

Your complete turnkey MASH units from study to commissioning

MASH Food Units

MASH Food Plants

TOY Group produces complete sets for the manufacture of the food, incorporating Flats-Flaky or Rolling Mills on blenders. All of our models of flatteners and rolling mills can be combined with all our blender models. These sets make the rolling of the grain, the integration of all the correctors and supplements, their mixtures to obtain a finished food.

The set can be weighed and controlled manually or automated. Within our group, through the TOY company, we also offer all handling and distribution storage equipment.

TOY GROUP FOOD GRANULATION UNITS: 7 CUSTOM CONFIGURATIONS – WITH OR WITHOUT CRUMBLES – 0.4 TO 0.7T/H THROUGH 10 TO 12 T/H

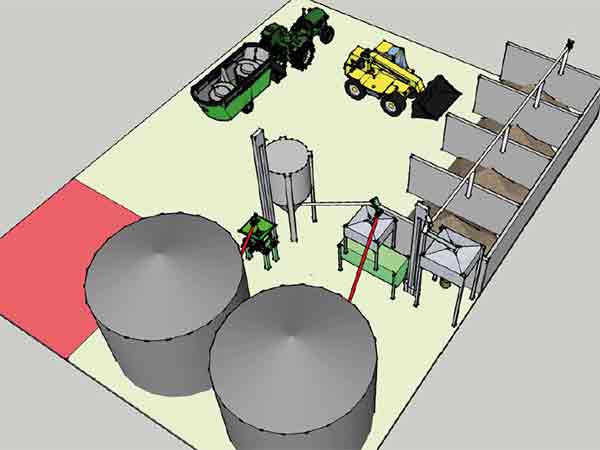

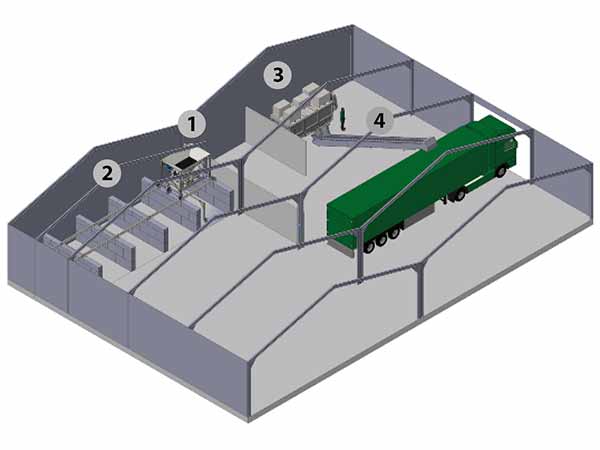

MASH Production Unit

TOY Group produces complete sets for the manufacture of the food, incorporating Flats-Flaky or Rolling Mills on blenders. All of our models of flatteners and rolling mills can be combined with all our blender models. These sets make the rolling of the grain, the integration of all the correctors and supplements, their mixtures to obtain a finished food.

The set can be weighed and controlled manually or automated. Within our TOY group, we also offer all handling and distribution storage equipment.

1/ Industrial rolling mill

2/ Storage

3/ Industrial mixer (catalogue or bespoke

4/ Conveyor carpet

Mash food unit: principle.

Supply of the rolling mill is very often done from the base of a loader (buckets). Cereals and proteins are stored in concrete boxes. The principle is simple one supplies the rolling mill installed on a rail above several boxes (number of boxes to be defined depending on production requirements). The (1) manually (or automatically) moves to fill these product boxes (2) flaked. The power of the rolling mill as well as the diameter of the cylinders depend on the tonnage to be made (see rolling description) daily. The goal is to have a flaked product with minimal dust. (Note that a steam flake allows you to obtain a product that deconstructs much less). After filling the boxes the charger takes in each box of laminated buckets that it pours. In the mixer with a palic system (3) (see mixer description) that is equipped with a weighing with a large display (clearly visible from the charger’s cabin), once the mixer is loaded with the various products that make up the ration and the mixture is completed, a carpet (5) installed at the end of the mixer evacuates the mixture without deconstructing it towards the loading.

Some facilities mash TOY Group

Industry Contacts

Industry salesman : Benjamin Ollivier

Tel: 06 80 33 12 38

b.ollivier@toy-sa.com

Industry Project Assistant: Muriel Faucheux

Tel: 02 54 85 29 63

m.faucheux@toy-sa.com

General reception desk

Tel: ’33 (0)2 54 85 01 10

Fax: ’33 (0)2 54 72 60 67

info@toy-sa.com

TOY Group Montoire sur le Loir

Route des Reclusages 41800 Montoire sur le Loir