TOY Group Mixers

Vertical mixers, horizontal mixers, tube mixers, a range of efficient machines

TOY Group Mixer Ranges

We present the TOY Group range of blenders and accessories. Reliable, solid, economical machines, designed and manufactured with great rigor to best and sustainably meet your needs. Our desire: to make you benefit always, from the best of the technique to the right value for your profitability, for the quality of your productions, for the comfort of your teams and yourself.

*Approximately depending on configuration. Non-contract photos and info, subject to change without notice – see us

Horizontal mixers

TOY Group Horizontal Mixers

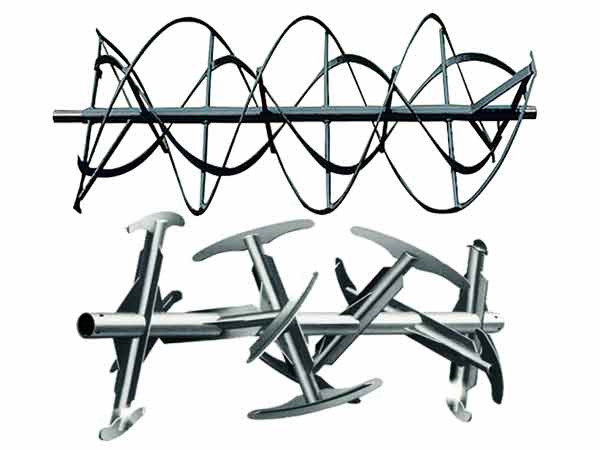

Capacity from 120 to 6000 litres, mixing by double-winding screws or blades system (ideal for fragile products). Chain transmission and an under crankcase geared motor . Rotation speed: 15 rpm / powers from 0.25 to 18.5 kW. Rolled thick steel precise fit tank, with all TOY know-how.

From 120 to 6000L. A double winding hold back or blades. Transmission: chain, geared motor or direct transmission. Power from 0.25 to 18.5 kW. Steel or INOX.

Commercial Doc Mixers

TOY Group Horizontal Mixers

Group TOY horizontal mixers have a capacity of 120 to 6000 liters, the mixture is either by a double-winding screw hold back or by a system of blades (ideal for fragile products). Silent transmission by chain and an crankcase geared motor. Rotation speed: 15 rpm / powers from 0.25 to 18.5 kW. The screw is adjustable and allows maximum extraction of the product. In thick and quality sheet metal, the tank is rolled with all our know-how for a precise adjustment (lower curve). The palic system offers a mixture without deconstructing delicate products (flattened, granulated, etc.). Indeed, the blades allow a discontinuous brewing compared to a double spire and thus limit the contact of the product with the surface of the blender. The draining of the pale blender is only ventral (at 800mm high of the ground): the arrangement of its pale counters prevents the product from crashing on the banks of the blender and thus preserves its texture. The inputs are incorporated from the top of the blender or by sticking flour at the end of the blender.

- From 120 to 6000 liters

- A double winding hold back or blades

- Transmission: chain, geared motor or direct transmission

- Max extraction by adjustable screw

- From 0.25 to 18.5 kW

- Accessible spires (removable side)

- Standard emptying at the end (many possible entry and exit options)

- Steel or INOX

Material:

- Gravity output with manual helmet valve

- Two rounds of decompression

| Horizontal mixer | Capacity (Ps 0.6) |

Geared motor | Long. (mm) | Width. (mm) | Top. (mm) | Top. ss hatch | Weight (kg) |

| 120 L |

60 kg |

0.25 kW | 1075 | 532 | 1806 | 800 |

85 |

| 200 L |

100 kg |

0.75 kW | 1475 | 532 | 1806 | 800 |

135 |

| 500 L |

250 kg |

1.5 kW | 1764 | 836 | 1788 | 800 |

260 |

| 1000 L |

500 kg |

3 kW | 2413 | 956 | 1943 | 800 |

500 |

| 1500 L |

750 kg |

4 kW | 1974 | 1148 | 2082 | 800 |

720 |

| 2200 L |

1000 kg |

5.5 kW | 2727 | 1156 | 2084 | 800 |

1085 |

| 3000 L |

1500 kg |

7.5 kW | 3577 | 1156 | 2084 | 800 |

1280 |

| 4500 L |

2000 kg |

11 kW | 3538 | 1380 | 2322 | 800 |

1650 |

| 4500 L (TD) |

2000 kg |

15 kW | 3716 | 1845 | 2322 | 800 |

1650 |

| 6000 L (TD) |

3000 kg |

18.5 kW | 3901 | 1970 | 2709 | 800 |

2000 |

(TD: Direct transmission)

TOY Horizontal Mixers Accessories/Options

Options:

- Flour intake flange – 100 or 160mm diameter

- Gravity output with automated helmet valve

- Ventral exit by guillotine hatch

- Ventral output by bridle at the end of the blender

- Ventral exit with bridle for back-up lock

- Direct training by industrial geared motor

Accessories and options:

- For horizontal mixers

- For tube mixers

Tube Mixers

TOY Group Tube Mixer

A revolution in the mix. Naturally anti-fouling design (precise fit between the spire and the tank) a self-cleaning blender for complete emptying and an efficient and fast mixture. Makes mixtures of great homogeneity, (tests carried out with tracer at 100 g/tonne.

1200 to 4500L. From 5.5 to 22 kW. A quality/safety revolution. Fast, homogeneous blend (IFIP test) in 3 to 6 minutes Extraction and maximum cleaning of the product by adjusting screws.

Commercial Doc Mixers

TOY Group Tube Mixers

The René TOY tube blender has a naturally anti-fouling shape: the precise fit between the spire and the tank makes this blender self-cleaning while allowing complete emptying and an efficient and fast blend. The very strong and waterproof thick sheet is rolled with great precision for optimal vat/spires fit. Our tube blender makes mixtures of great homogeneity, tests carried out with a tracer embedded at 100 g/tonne. The drain is done by a gravity output at the end of the standard version blender (at 800mm from the ground). The products are incorporated from the top of the blender or by collecting flour at the end of the blender.

- 1200 to 4500 litres

- A quality/safety revolution

- Silent transmission: chain, motor operator or direct transmission

- Mix of speed and homogeneity (IFIP test) in 3 to 6 minutes

- Access to spires (removable side)

- Standard end or ventral drain on demand

- Maximum extraction and cleaning of the product by adjusting screws

- 5.5 to 22 kW

The technique:

- Waterproof mixer with special seal bearings (possibility of depressurizing it)

- Motor drive (right or elbow)

- Transmission per chain

- A double spires upset

Material:

- Gravity output with manual helmet valve

- Two rounds of decompression

TOY Group Tube Mixers Accessories and Options

Options:

- Flour intake flange – 100 or 160mm diameter

- Gravity output with automated helmet valve

- Ventral exit by guillotine hatch

- Ventral output by bridle at the end of the blender

- Ventral exit with bridle for back-up lock

- Direct drive by industrial engine (right or bent)

- Pneumatic food factory

Accessories and options:

- For horizontal mixers

- For tube mixers

Vertical mixers

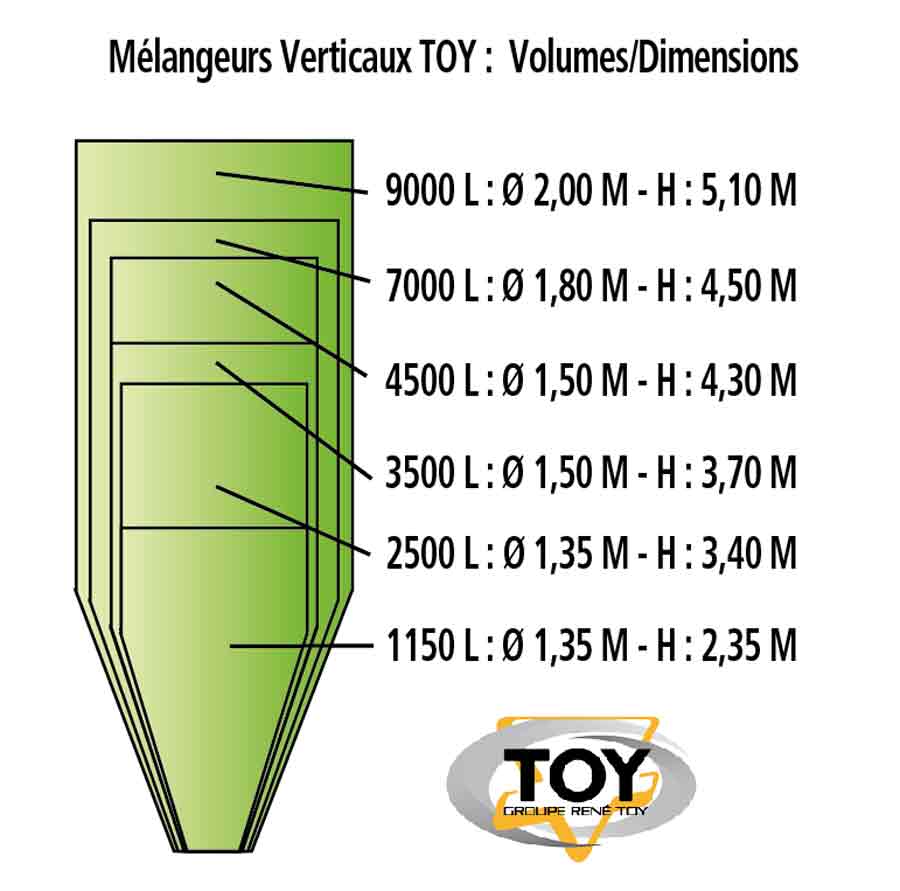

TOY Group Vertical Mixers

With a capacity of 1150 to 4500 liters. Mixed with a central screw, with a not-ending mesh start and an anti-vault knife. Rotation of 270 rpm. Engine from 1.5 to 5.5 kW. The average mixing time is 20 minutes per tonne. The drain is done by a gravity exit.

From 1150 to 4500L. Rotation of 270 rpm. Engine from 1.5 to 5.5 kW. Medium mix 20 minutes per tonne. Drain by gravity exit.

Commercial Doc Mixers

TOY Group Vertical Mixers

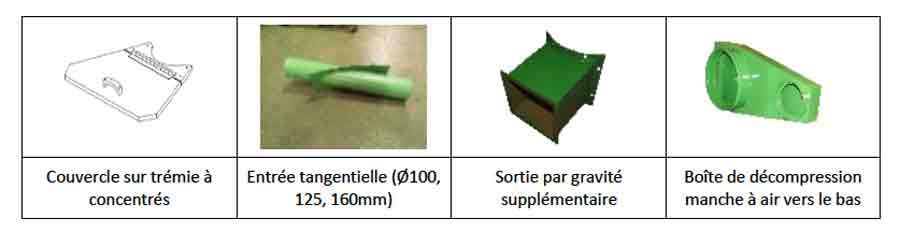

Our vertical blenders have a capacity of 1150 to 4500 liters. The mixture is made by a central screw, with a not fine mesh start and an anti-vaulting knife. Its rotation speed is 270 rpm with an engine of 1.5 to 5.5 kW. The average mixing time is 20 minutes per tonne. The drain is done by a gravity exit (at 800mm from the ground) and the incorporation of the inputs is done, either by a tangential input (in pneumatics) or by the hopper concentrated at the foot of the blender.

- 1150 to 4500 litres

- Simple, accessible and economical

- Central screw: start not fine net with anti-vaulting knives (with access hatch)

- Decompression up, decompression option down (-2 meters with decompression box)

- 50-litre concentrate hopper

- Tangential entrance, drain trap, gravity exit

Material:

- Gravitational exit with guillotine trap

- Drain door at the foot of the screw for easy cleaning

- Concentrated hopper (height 730mm)

- Access door to the anti-vaulting knife of flours

- Two rounds of decompression

Options:

- Tangential Entry – 100 or 160mm

- Automated gravitational output

- Decompression box and decompression handle for low-rise building

TOY Group Vertical Mixers

Dimensions by volume:

Options:

- Tangential Entry – 100 or 160mm

- Automated gravitational output

- Decompression box and decompression handle for low-rise building

Download the mixer options table

Stainless blenders

Stainless steel mixers TOY Group

TOY Group know-how for entirely stainless steel manufacturing (for industry, food, chemical industry or any other industrial field requiring optimum sanitary quality. Our experience in weighing, dosing, microdosing complements our range of specific materials. All capacity from 30 liters.

Manufacturing entirely in stainless steel (for industry, food, chemical industry. An optimum sanitary quality. All capacity from 30 liters.

Commercial Doc Mixers

Stainless steel mixers TOY Group

Our state-of-the-art machine equipment and the know-how of René TOY men, position us powerfully on the manufactures entirely in stainless steel. For areas of activity such as the food industry, or chemical industry or any other industrial area requiring optimum sanitary quality. Our experience in weighing, dosing, microdosing complements your needs and the requirements of your productions. We offer all capacities from 30 liters.

Don’t hesitate to consult us: our technical-commercial specialist in this field will advise you.

Dosing/Weighing

Weighing sensors, weighing frames…

TOY Group offers weighing solutions adapted to its equipment and various processes (food manufacturing and others). Chassis weighs 3 or 4 gauges to measure, depending on the equipment mounted. Individual weighing sensors for mixers, load bushels, etc.

TOY Group Mixers

TOY Group Contact Information

General reception desk

Tel: ’33 (0)2 54 85 01 10

Fax: ’33 (0)2 54 72 60 67

info@toy-sa.com

TOY Group Sites:

TOY Group Montoire sur le Loir

Route des Reclusages 41800 Montoire sur le Loir

TOY Group Saint Amand Longpré

16 rue de l’Industrie 41310 Saint Amand Longpré

TOY Group Brittany

3 PA des Landes de Penthièvre 22640 PLESTAN