UCG – Compact Granulation Unit

Wood-energy granulation – Biomass valuation

UCG – Wood-energy granulation

Granulation Compact Unit

The UCG – Compact Granulation Unit – is intended to equip you with a wood-energy biomass recovery tool (short-track co-products). TheUCG meets the needs and expectations of a valued and concentrated energy in the form of pellets. The compact sizing of this production unit allows it to take place in a chain of renewable energy needs of many communities and public, private, or mixed facilities.

WOOD-ENERGY BIOMASS VALUATION (SHORT-CHANNEL CO-PRODUCTS). UCG MEETS THE NEEDS OF A VALUED AND CONCENTRATED ENERGY IN THE FORM OF PELLETS

The 5 main objectives of the UCG.

The Granulation Compact Unit is designed to provide you with a tool to enhance your short-form products from the producer to consumers. This TOY Group equipment meets 5 objectives:

Goal 1:

The UCG is compact, self-contained, and budget-efficient.

Goal 2:

It is at the forefront of a very buoyant market in strong development.

Goal 3:

It incorporates the notion of proximity between producers and consumers.

Goal 4:

It meets the needs and expectations of energy valued and concentrated in the form of pellets.

Goal 5:

Because of its size and function, it fits perfectly into sustainable development issues.

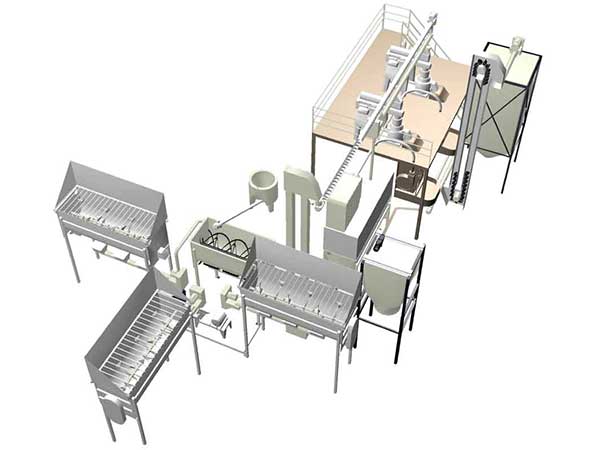

Composition of a UCG

1 Food

Feeding hoppers can empty the contents of a big bag or a small bucket. They are equipped with:

- A dynamic dedication that allows the perfect flow of matter;

- A protective grid

- a recovery screw under the hopper, ensuring the extraction of the material.

2 Incorporation of additives

A special hopper allows very precisely to incorporate and dose additives in powder form.

3 Weighing – dosing

As soon as the products enter the Compact Granulation Unit, they are weighed continuously. This allows the proportion of each raw material to be accurately defined.

4 Grinding

A pre-shredder followed by a hammer grinder (refiner) reduces granulometry:

- The pre-shredder splits coarse elements (clods, dumplings, shards);

- the refiner is equipped with hammers (steel blades) the material passes through a perforated grid. The material is reduced to the state of flour to give the final granule a flawless appearance.

5 Mix

- The ribbon mixer mixes the different raw materials.

- A spray of water corrects, if necessary, the moisture of the product.

- The mixture is then transferred by handling equipment (elevator and archimedes screw) to the UCG.

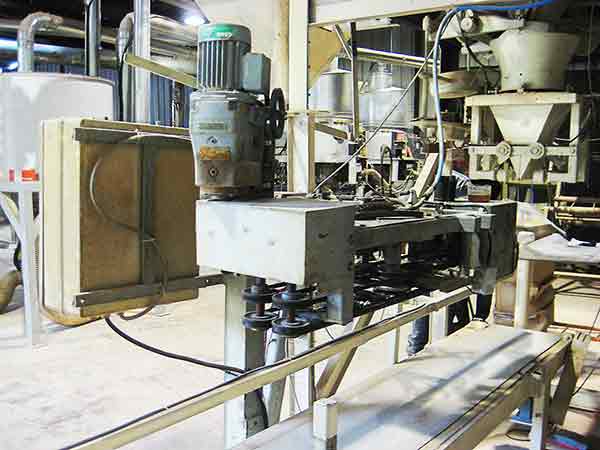

6 Granulation

The presses do the work of compacting the material by forcing it to cross the compression channels of the chain. The presses do this work with two compression rollers. The volume of the material is reduced by 4 and the pellets obtained have a temperature of around 100oC.

7 Cooling

Cooling involves passing air to room temperature in the bed of pellets. The horizontally circulating air absorbs the heat contained in the pellets, on contact with the fresh air these cool. The sieve below the cooler removes the fine before the pellets are stored or bagged.

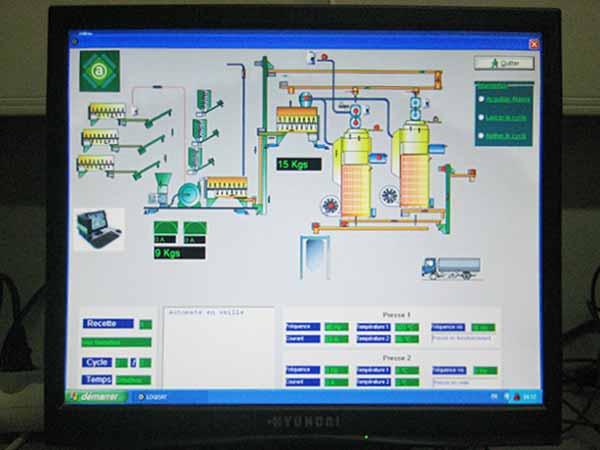

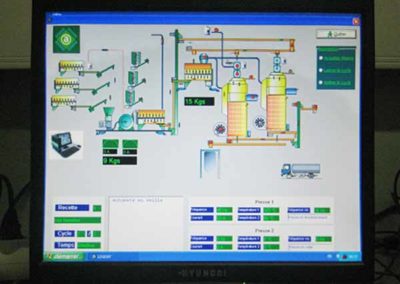

AUTOMATION / COMMANDS (OPTIONS):

René TOY develops numerous automated management and steering systems for all phases of a production process (Power Cabinets, Dynamic or Fixed Synoptics, Level Control, PC Management, Transfer Management, Temperature Sensors.

Other:

The TOY Group also produces the complete equipment and facilities for the storage, bagging, packaging and/or distribution of finished pellets.

Some UCG TOY Group facilities

Industry Contacts

Industry salesman : Benjamin Ollivier

Tel: 06 80 33 12 38

b.ollivier@toy-sa.com

Industry Project Assistant: Muriel Faucheux

Tel: 02 54 85 29 63

m.faucheux@toy-sa.com

General reception desk

Tel: ’33 (0)2 54 85 01 10

Fax: ’33 (0)2 54 72 60 67

info@toy-sa.com

TOY Group Montoire sur le Loir

Route des Reclusages 41800 Montoire sur le Loir